1.Ithini indima ye-elementi ngayinye ku-diamond saw blade matrix binder?

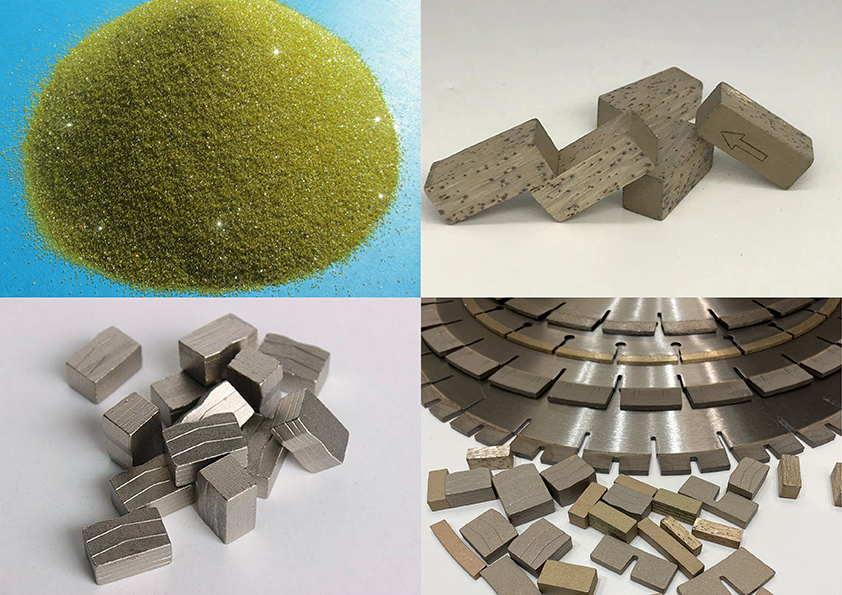

Indima yethusi: Ama-alloys asekelwe ethusi nawethusi yizinsimbi ezisetshenziswa kakhulu kumathuluzi edayimane ahlanganisa insimbi, kanti impushana yethusi ye-electrolytic iyona esetshenziswa kakhulu.Ama-alloys asekelwe ethusi nawethusi asetshenziswa kakhulu ngenxa yokuthi ama-binder asekelwe ethusi anezici ezihlanganisayo ezanelisayo: izinga lokushisa eliphansi le-sintering, ukuhleleka okuhle nokuhlangana, kanye nokuxubeka nezinye izakhi.Nakuba ithusi lingenakumanzisa amadayimane, izakhi ezithile kanye nama-alloys ethusi kungathuthukisa kakhulu ukumanzisa kwazo kumadayimane.Enye yezinto ezifana ne-Cr, Ti, W, V, Fe eyenza ithusi nama-carbides ingasetshenziswa ukwenza ama-alloys ethusi, anganciphisa kakhulu i-angle yokumanzisa yama-alloys ethusi kumadayimane.I-solubility yethusi ensimbi ayiphezulu.Uma kunethusi eliningi ensimbi, linciphisa kakhulu ukusebenza kokushisa futhi libangele ukuqhekeka kwezinto.I-Copper ingakha izixazululo ezihlukahlukene eziqinile nge-nickel, i-cobalt, i-manganese, ithini, ne-zinc, iqinisa insimbi ye-matrix.

Umsebenzi we-tin: Ithini i-elementi enciphisa ukungezwani okungaphezulu kwama-alloys oketshezi futhi inomphumela wokunciphisa i-engeli yokumanzisa yama-alloys anguketshezi kumadayimane.Kuyisici esithuthukisa ukumanziswa kwezinsimbi eziboshiwe kumadayimane, enciphisa indawo encibilikayo yama-alloys, futhi ethuthukisa ukwakheka kokucindezelwa.Ngakho-ke i-Sn isetshenziswa kakhulu kuma-adhesives, kodwa ukusetshenziswa kwayo kunqunyelwe ngenxa ye-coefficient yayo enkulu yokwandisa.

Iqhaza le-zinc: Kumathuluzi edayimane, i-Zn ne-Sn inokufana okuningi, njengendawo encibilikayo ephansi kanye nokukhubazeka okuhle, kuyilapho i-Zn ingalungile ekuguquleni ukumanzisa kwedayimane njengo-Sn.Umfutho we-vapor we-Zn yensimbi uphezulu kakhulu futhi kulula ukuwufaka i-gasify, ngakho-ke kubalulekile ukunaka inani le-Zn elisetshenziswa kuma-binders amathuluzi edayimane.

Indima ye-aluminium: I-aluminium yensimbi iyinsimbi ekhanyayo enhle kakhulu kanye ne-deoxidizer enhle.Ku-800 ℃, i-engeli yokumanzisa ye-Al edayimane ingu-75 °, futhi ku-1000 ℃, i-engeli yokumanzisa ngu-10 °.Ukwengeza impushana ye-aluminium kusibophezelo samathuluzi edayimane kungakha isigaba se-carbide i-Ti Å AlC kanye nenhlanganisela ye-intermetallic TiAl kungxubevange ye-matrix.

Indima yensimbi: I-ayoni inendima embaxambili kusibophezelo, enye iwukwenza ama-carburized carbides ngamadayimane, kanti enye iwukuba ingxubevange nezinye izakhi ukuqinisa i-matrix.Ukumanzisa kwensimbi nedayimane kungcono kunokwethusi ne-aluminium, futhi umsebenzi wokunamathisela phakathi kwensimbi nedayimane uphakeme kunowe-cobalt.Uma inani elifanelekile lekhabhoni lincibilika kuma-alloys asekelwe ku-Fe, kuzoba nenzuzo ekuxhumaneni kwawo namadayimane.Ukufakwa okumaphakathi kwamadayimane ngama-alloys asekelwe ku-Fe kungakhuphula amandla okubopha phakathi kwebhondi nedayimane.Indawo ephukile ayibushelelezi futhi ingenalutho, kodwa imbozwe ungqimba lwe-alloy, okuwuphawu lwamandla okubopha okuthuthukisiwe.

Indima ye-cobalt: I-Co ne-Fe ingeyezakhi zeqembu lenguquko, futhi izici eziningi ziyefana.I-Co ingakha i-carbide Co ₂ C ngedayimane ngaphansi kwezimo ezithile, kuyilapho isakaza ifilimu ye-cobalt ezacile kakhulu ebusweni bedayimane.Ngale ndlela, i-Co inganciphisa ukungezwani kwangaphakathi kobuso phakathi kwe-Co nedayimane, futhi inomsebenzi obalulekile wokunamathisela idayimane esigabeni soketshezi, iyenze ibe into enhle kakhulu yokubopha.

Indima ye-nickel: Ku-binder yamathuluzi edayimane, i-Ni iyinto ebaluleke kakhulu.Kuma-alloys asekelwe ku-Cu, ukungezwa kwe-Ni kungancibilika ngokungenamkhawulo nge-Cu, kuqinise ingxubevange ye-matrix, kucindezela ukulahleka kwensimbi okuncibilika okuphansi, futhi kwandise ukuqina nokumelana nokugqokwa.Ukwengeza ama-alloys e-Ni ne-Cu ku-Fe kungehlisa izinga lokushisa le-sintering futhi kunciphise ukugqwala okushisayo kwezinsimbi eziboshiwe kumadayimane.Ukukhetha inhlanganisela efanele ye-Fe ne-Ni kungathuthukisa kakhulu amandla okubamba ama-binder asekelwe ku-Fe kumadayimane.

Indima ye-manganese: Kuma-binders ensimbi, i-manganese inomthelela ofanayo ne-iron, kodwa inamandla okungena okuqinile kanye nekhono lokukhipha umoya-mpilo, futhi ijwayele ukungena kwi-oxidation.Inani elingeziwe le-Mn ngokuvamile aliphezulu, futhi okucatshangelwayo okuyinhloko ukusebenzisa i-Mn ye-deoxidation ngesikhathi sokuhlanganiswa kwe-sintering.I-Mn esele ingabamba iqhaza ekuhlanganiseni nasekuqiniseni i-matrix.

Iqhaza le-chromium: I-Metal chromium iyisici esiqinile esenza i-carbide futhi iyisici esisetshenziswa kakhulu.Ku-diamond groove saw blade matrix, kune-chromium eyanele yokuba nomsindo wokunciphisa umsindo, ohlobene namandla okuqalisa e-Cr.Ukwengeza inani elincane le-Cr ku-matrix esekelwe ku-Cu kunganciphisa i-engeli yokumanzisa ye-alloy esekelwe ethusi ukuya edayimaneni futhi kuthuthukise amandla okubopha wengxubevange esekelwe ethusi ukuya edayimaneni.

Indima ye-titanium: I-Titanium iyisici esiqinile esakha i-carbide okulula ukusikhipha i-oxidize futhi okunzima ukuyehlisa.Lapho kukhona umoya-mpilo, i-Ti ikhiqiza ngokukhethekile i-TiO2 esikhundleni se-TiC.Insimbi ye-Titanium iyisakhiwo esihle esinamandla aqinile, inciphisa amandla amancane emazingeni okushisa aphezulu, ukumelana nokushisa, ukumelana nokugqwala, kanye nendawo ephezulu yokuncibilika.Ucwaningo luye lwabonisa ukuthi ukwengeza inani elifanele le-titanium ku-matrix ye-saha yedayimane kunenzuzo ekuthuthukiseni impilo yesevisi ye-saha blade.

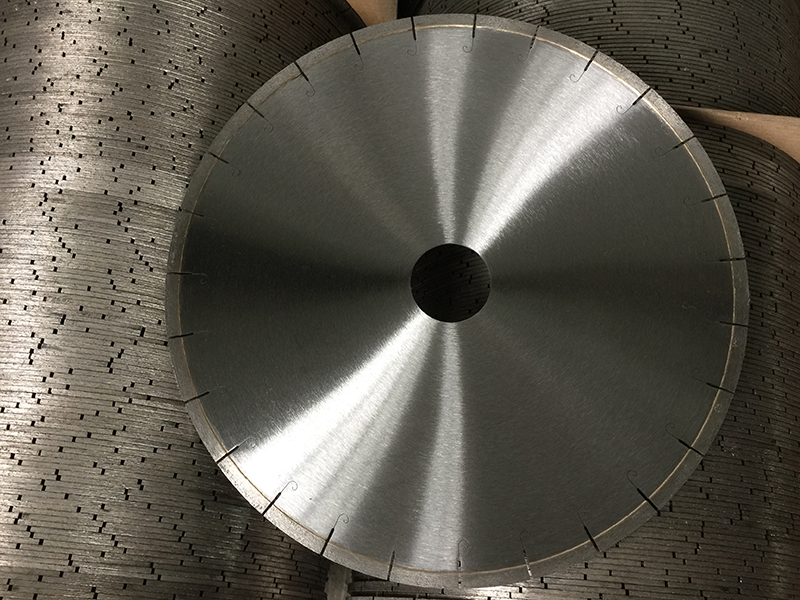

2.Kungani umzimba wesaha kufanele ufane netshe lokusika?

Izindlela eziyinhloko zokuhlukaniswa kwamadwala phakathi nenqubo yokusika i-saw blade ziqhekeka futhi zichotshozwe, kanye nokugunda kwevolumu enkulu nokuhlukaniswa, okuhambisana nokugaya kwendawo.Idayimane elinendawo yokusebenza ene-serrated esebenza njengethuluzi lokusika.Umkhawulo wayo wokusika uyindawo ye-extrusion, indawo yokusika iphambi komkhawulo, futhi indawo yokugaya ingemuva.Ngaphansi kokusika ngesivinini esikhulu, izinhlayiya zedayimane zisebenza ekusekelweni kwe-matrix.Phakathi nenqubo yokusika itshe, ngakolunye uhlangothi, idayimane lithola i-graphitization, ukuhlukaniswa, nokuhlukaniswa ngenxa yokushisa okuphezulu okukhiqizwa ukungqubuzana;Ngakolunye uhlangothi, i-matrix igqokwa ukungqubuzana nokuguguleka kwamatshe nompuphu wamatshe.Ngakho-ke, indaba yokuguquguquka phakathi kwama-saw blades namatshe empeleni iyinkinga yezinga lokugqoka phakathi kwedayimane ne-matrix.Isici sethuluzi elisebenza ngokujwayelekile ukuthi ukulahlekelwa kwedayimane kufana nokuguga kwe-matrix, okugcina idayimane lisesimweni esivamile sokusika, kungekona ukuqoqwa ngaphambi kwesikhathi noma ukugaya idayimane elibushelelezi nelishelelayo, okuqinisekisa ukuthi umphumela walo wokugaya usetshenziswa ngokugcwele. ngesikhathi sokusebenza, okuholela ekutheni amadayimane engeziwe abe sesimweni sokuphuka nokuguga kancane.Uma amandla nomthelela wokuphikiswa kwedayimane ekhethiwe kuphansi kakhulu, kuzoholela esenzweni "sokushefa", futhi isikhathi sokuphila sethuluzi sizoba sincane futhi i-passivation izoba nzima, futhi ngisho nokusaha ngeke kuhambe;Uma kukhethwa izinhlayiya eziqhumayo ezinamandla amakhulu kakhulu, unqenqema lwezinhlayiya ezilumayo luzovela esimweni esicaba, okuholela ekwandeni kwamandla okusika kanye nokuncipha kokusebenza kahle kokucubungula.

(1) Uma isivinini sokuguga se-matrix sikhulu kunedayimane, kuholela ekusikeni kwedayimane ngokweqile kanye nokuhlukaniswa ngaphambi kwesikhathi.Ukumelana nokugqoka komzimba we-saw blade kuphansi kakhulu, futhi impilo ye-saw blade ifushane.

(2) Uma ijubane lokuguga le-matrix lingaphansi kweledayimane, idayimane elisha alivezwa kalula ngemva kokuba unqenqema lokusika lwedayimane lugugile, ama-serration awanawo umphetho wokusika noma umphetho wokusika uphansi kakhulu, ingaphezulu ama-serrations adlulisiwe, ijubane lokusika lihamba kancane, futhi kulula ukubangela ibhodi elisikiwe ukuba liwe, elithinta ikhwalithi yokucubungula.

(3) Uma isivinini sokuguga se-matrix silingana nesivinini sokuguga sedayimane, sibonisa ukuhambisana kwe-matrix netshe elisikiwe.

Isikhathi sokuthumela: Aug-11-2023