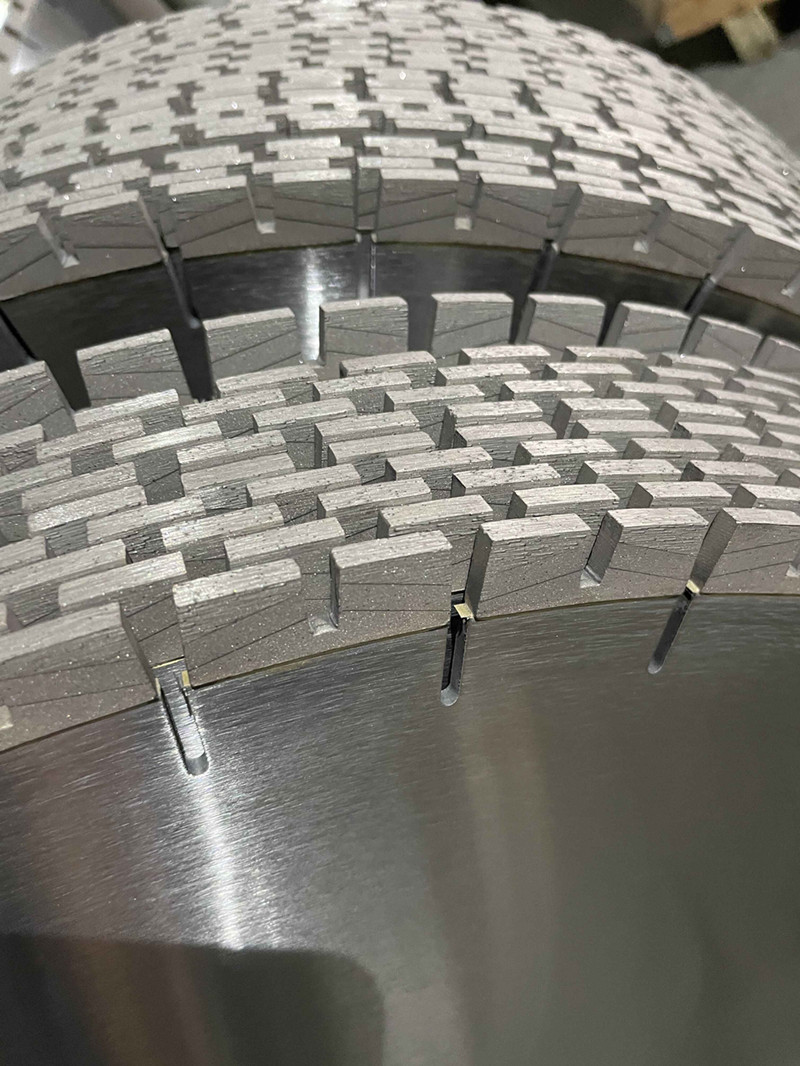

1.Hlola ububanzi bangaphakathi nangaphandle bamasaha, ukujiya kanye nenani lamazinyo e-substrate ngokwezidingo zokukhiqiza, bese uhlola ukucaciswa, ubuningi kanye ne-radian yengxenye yedayimane.Bese ugaya i-chamfer yangaphandle ye-substrate emishini yokugqoka.Hlanza indawo yokushisela yesisekelo kanye nengxenye nge-switch C, bese usebenzisa i-ejenti yokunamathisela.

2.Khetha i-welding blade efanele ngokusho kwesici se-saw blade ezidingweni zokwakha.Ububanzi be-welding blade ngokuvamile bukhulu ngo-0 kunobukhulu besisekelo.Ubukhulu be-welding blade buzoba ngu-0.25-0.30mm lapho ushisela i-saw blade enobubanzi obungu-5-1 mm nangaphezulu kuka-1500mm;Lapho ushisela i-saw blade enobubanzi obungaphansi kuka-1500mm, ubukhulu bensimbi yokushisela buzoba ngu-0.15 ~ 0.25mm.

3.Faka isisekelo, lungisa indawo, qinisa izikulufu zokulungisa, faka i-splint yokupholisa, lungisa i-segment pushing device kanye ne-segment clamp, lungisa izinga lokushisa lokushisela, ukugcinwa kokushisa kanye nesikhathi sokupholisa ngokuvumelana nezidingo zenqubo, futhi ufeze. ukushisela.

4.Lapho ushisela i-saw blade ngemishini ye-high-frequency, zungezisa isisekelo ngo-180 ° C engxenyeni ngayinye eshiselwe, ukuze ushise ngokulinganayo ukugwema ukucwiliswa kwe-anneal noma ukuguqulwa kwendawo okubangelwa ukushisa ngokweqile kwesisekelo.

5.Uma ushisela i-gang saw blade, weld ingxenye endaweni eshiwo ngokusho kwesakhiwo sezinyo.

6. Ngemuva kokushisela i-saw blade, kuzokwenziwa ukuzihlola.

Isikhathi sokuthumela: Mar-04-2023