1. Yini i-aidayimane indilinga isaha blade

Isaha esiyindilinga sedayimaneiyithuluzi lokusika elivame ukusetshenziswa, okuyisaha elinomphetho wokusika wedayimane elitholakala ngaphakathi noma ngaphandle kwesiyingi se-saw blade.Isetshenziswa kabanzi ekucubunguleni izinto eziqinile neziphukayo njengamatshe nezitsha zobumba.I-diamond saw blade ngokuyinhloko iqukethe izingxenye ezimbili: i-substrate kanye ne-blade.I-substrate iyingxenye eyinhloko yokusekela ye-adhesive blade, kuyilapho i-blade iyingxenye yokusika eqala ngesikhathi sokusetshenziswa.I-blade izodla ngokuqhubekayo ngesikhathi sokusetshenziswa, kanti i-substrate ngeke.Izinhlayiya zedayimane zisongwe ngensimbi ngaphakathi kwekhanda lokusika, elidlala indima yokusika ekusikeni kokungqubuzana kwento ecutshungulwayo phakathi nenqubo yomshini.Ngesikhathi sokusetshenziswa, i-matrix yensimbi nedayimane kudliwa ndawonye.Ngokuvamile kulungele ukuthi i-matrix yensimbi idle ngokushesha kunedayimane, okuqinisekisa kokubili ubukhali bekhanda lokusika kanye nempilo yesevisi yekhanda lokusika.

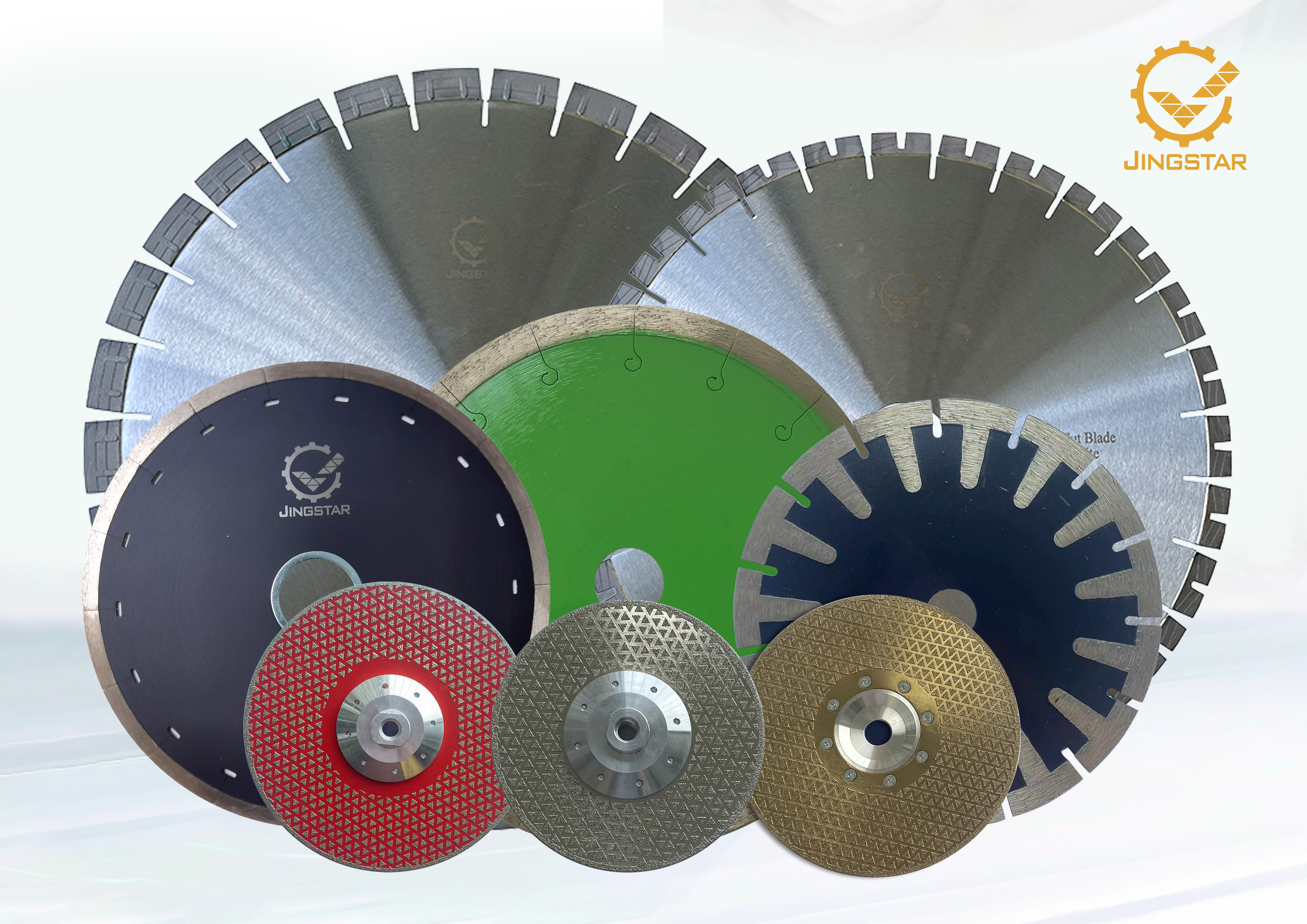

Ububanzi be-diameter ofama-saha ayindilinga wedayimaneinkulu, inezindwani ezibaziweyo ezingamamilimitha amaningana namasaha amakhulu angamamitha amaningana ububanzi.Kukhona futhi izinto eziningi zokusika, futhi isakhiwo, ubulukhuni, nobukhulu bezinto zokusika ziyahlukahluka kakhulu.Ngakho-ke, izindlela zabo zokucubungula nokukhiqiza, izinto ezingavuthiwe ezisetshenziswayo, kanye nezidingo zokusebenzisa zonke zihlukile.

2, Ukuhlukaniswa kweama-saha ayindilinga wedayimane

Isaha esiyindilinga sedayimaneokwamanje iyithuluzi lokusaha elisetshenziswa kakhulu embonini yamatshe yaseShayina, ngokuvamile eliyisiyingi ngesimo.Isebenzisa izindlela ezifana ne-powder metallurgy noma i-electroplating ukuze ishumeke izinhlayiya zedayimane ezizungeze i-substrate.Ukusebenzisa amandla aphezulu nobulukhuni bezinhlayiya zedayimane ukugunda nokuchoboza ezinye izinto ngezinhloso zokusika.Kunezinhlobo eziningi zeama-saha ayindilinga wedayimanefuthi ukuhlukaniswa kwazo kuyinkimbinkimbi kakhulu.Ngokuvamile kunezindlela ezimbalwa zokuhlukanisa:

1. Ukuhlukaniswa ngenqubo yokukhiqiza:

(1) Isaha ledayimane elicwebezelayo

Kunezinhlobo ezimbili ze-sintering: i-cold press sintering kanye ne-hot press sintering.

(2) Isaha ledayimane elishiselayo

Kunezinhlobo ezimbili ze-brazing kanye ne-Laser beam welding.I-Brazing iwukushisela ikhanda lokusika kanye ne-substrate ndawonye ngokusebenzisa izinga lokushisa eliphezulu elincibilikayo, njenge-high-frequency induction brazing saw blade, i-vacuum brazing saw blade, njll;Ukushisela nge-laser kusebenzisa izinga lokushisa eliphezulu kwe-laser ugongolo ukuncibilikisa ikhanda elisikayo kanye nonqenqema lokuxhumana lwe-substrate ukwenza isibopho se-metallurgical.

(3) Isaha ledayimane elifakwe ugesi

Kuyinqubo yokunamathisela i-blade powder ku-substrate ngokusebenzisa i-electroplating.Kodwa-ke, ngenxa yokungcola okukhulu, izwe liyayiqeda kancane kancane le ndlela yokufaka i-electroplating.

2. Ukuhlelwa ngokucubungula into:

I-Marble cutting saw blade, i-granite cutting saw blade, i-saw blade yokusika ukhonkolo, njll.

3. Ukuhlukaniswa ngokubukeka:

Amasaha onqenqema aqhubekayo, amasaha ohlobo lwe-blade, ama-saha ohlobo lwe-turbine, njll. Yebo, indlela yokuhlukanisa engenhla ayikwazi ukufaka zonkeama-saha ayindilinga wedayimane, futhi kunezinjongo eziningi ezikhethekileama-saha ayindilinga wedayimane.Khetha izinhlobo ezahlukene ze-diamond saw blades zokucubungula izinto ezahlukene.

3. Izici eziyinhloko zeidayimane indilinga isaha bladeukusika

Ukusika i-circular saw blade kunezinzuzo zokusebenza okulula, ukusebenza kahle okuphezulu, kanye nekhwalithi enhle yokucubungula.Kodwa umsindo uphezulu futhi ukuqina kwe-blade akulungile.Phakathi nenqubo yokusika, i-saw blade ijwayele ukudlidliza nokuchezuka, okuholela ekulinganiseni okungalungile kwesiqeshana sokusebenza esisikiwe.

4. Izinto ezithinta ukusebenza kahle nempilo yeama-saha ayindilinga wedayimane

Izinto ezithinta ukusebenza kahle nempilo yeama-saha ayindilinga wedayimanefaka imingcele yenqubo yokusika, ibanga ledayimane, usayizi wezinhlayiyana, ukugxila, nobulukhuni bebhondi.

1. Imingcele yokusaha

(1) Ijubane lokusika amasaha

Emsebenzini ongokoqobo, isivinini somugqa weama-saha ayindilinga wedayimanekunqunyelwe izimo zemishini, ikhwalithi ye-saw blade, kanye nezakhiwo zetshe ezisaha.Ngokuphathelene nempilo yesevisi kanye nokusebenza kahle kokusika kwe-saw blade, isivinini somugqa we-saw blade kufanele sikhethwe ngokusekelwe ezintweni zamatshe ahlukene.

(2) Ukujula kokusaha

Ngaphakathi kobubanzi obuvumelekile bokusebenza komshini wamasaha namandla ethuluzi, ukujula okukhulu kokusika kufanele kukhethwe ngangokunokwenzeka ukuze kuthuthukiswe ukusebenza kahle kokusika.Uma kunezidingo zendawo eyenziwe ngomshini, ukusika okuncane kokujula kufanele kusetshenziswe.

(3) Isivinini sokuphakelayo

Isivinini sokuphakela isivinini sokuphakela kwetshe elisahayo.Inani layo kufanele likhethwe ngokusekelwe ezicini zetshe esawn.Ngokuvamile, ukusaha amatshe athambile, njengemabula, kungakhuphula ukujula kokusaha futhi kunciphise isivinini sokudla, okusiza kakhulu ekuthuthukiseni izinga lokusaha.Ukusaha igwagwa elicolile kanye ne-homogeneous ngokuqhathaniswa kungakhuphula isivinini sokuphakela ngendlela efanele.Uma isivinini sokuphakela siphansi kakhulu, icwecwe ledayimane ligaywa kalula.Kodwa-ke, lapho usaha i-granite enokwakheka okusanhlamvu okumahhadlahhadla nobulukhuni obungalingani, ijubane lokusika kufanele lincishiswe, ngaphandle kwalokho lizokwenza ukuthi i-saw blade idlidlize futhi ibangele ukuhlukana kwedayimane, ngaleyo ndlela kunciphise izinga lokusika.

2. Usayizi wezinhlayiyana zedayimane

Usayizi wezinhlayiya zedayimane ovame ukusetshenziswa usukela ku-30/35 kuya ku-60/80 mesh.Uma idwala liqinile, kufanele kukhethwe ubukhulu bezinhlayiyana ezincane.Ngoba ngaphansi kwezimo ezifanayo zokucindezela, lapho idayimane licoleka, liba bukhali, okuzuzisa ukusika emadwaleni aqinile.Ukwengeza, ama-saha ama-diameter amakhulu ngokuvamile adinga ukusebenza kahle kokusika, futhi osayizi bezinhlayiyana eziqinile njenge-30/40 mesh kanye ne-40/50 mesh kufanele kukhethwe;Ama-saha ama-diameter amancane asebenza kahle kakhulu futhi adinga izigaba zokusika ezibushelelezi.Kutuswa ukuthi ukhethe osayizi bezinhlayiyana abacolekile, njenge-50/60 mesh kanye ne-60/80 mesh.

3. Ukugxila kwedayimane

Ukugxiliswa kwedayimane kusho ukuminyana kokusatshalaliswa kwedayimane ku-matrix yesendlalelo esisebenzayo.Ngokusho kwemithethonqubo, ukuhlushwa kwe-4.4 carats yedayimane nge-cubic centimeter ngayinye ye-matrix ye-work layer yi-100%, kanti ukuhlushwa kwe-3.3 carats yedayimane kungama-75%.Ukugxiliswa kwevolumu kumelela umthamo wedayimane kubhulokhi futhi kucacisa ukuthi ukugxiliswa ku-100% lapho ivolumu yedayimane ibala u-1/4 wevolumu iyonke.Ukwenyusa ukugcwala kwedayimane kulindeleke ukuthi kunwebe isikhathi sempilo yensingo yesaha, njengoba ukukhulisa ukugxilisa ingqondo kunciphisa isilinganiso samandla okusika idayimane ngalinye.Kodwa ukukhulisa ukugxilisa ingqondo kuzozikhuphula nakanjani izindleko zesaha, ngakho-ke kukhona ukugxila okonga kakhulu okwandayo ngokwanda kokusebenza kokusaha.

4. Ukuqina kwe-cutter head binder:

Ngokuvamile, ukuphakama kokuqina kwesibopho, kuqina ukumelana nokugqoka kwayo.Ngakho-ke, lapho ubona amatshe ane-abrasiveness ephezulu, ubulukhuni be-binder buphakeme kalula;Uma ubona amatshe athambile, ubulukhuni be-binder kufanele bube buphansi;Uma ubona amatshe ane-abrasiveness ephezulu nobulukhuni, ubulukhuni be-binder kufanele bulinganise.

5, Ithrendi Yentuthuko yeAma-Saw Blades ayindilinga yedayimane

Ama-saw blades ayindilinga yedayimaneangamathuluzi ayinhloko embonini yokucubungula amatshe.Eminyakeni yamuva nje, inani lamadayimane okwenziwa asetshenziswa embonini yokucubungula amatshe likhuphuke kakhulu, futhi ukusetshenziswaama-saha ayindilinga wedayimaneliyakhula futhi.Sekukonke, ukuthuthukiswaama-saha ayindilinga wedayimanekokubili ngaphakathi nangaphandle kwezwe kunezici ezilandelayo: ukukhiqiza ama-saha ama-blade asebenza kahle futhi aphezulu, kanye nokuthuthukisa amadayimane akhethekile ebanga le-saha blade;Naka kakhulu ucwaningo lwempushana, i-matrix, kanye nenqubo ye-sintering;Naka kakhulu ucwaningo mayelana ne-sawability kanye nendlela yokubona izinto zamatshe;Laser welding saw blade iye yathuthukiswa;Thuthukisa ubukhulu obukhuluama-saha ayindilinga wedayimane.Njengamanje, ukusetshenziswa kweama-saha ayindilinga wedayimaneiya ngokuya isakazeka.Esikhathini esizayo, isiqondiso ukuthuthukiswaama-saha ayindilinga wedayimaneukuthuthukisa ukusebenza kahle kokusika, impilo ye-saha blade, ukunciphisa izindleko zokukhiqiza, kanye nokufeza ukuvikelwa kwemvelo.

Inkomba: "I-Q&A Yamathuluzi Edayimane Nedayimane" ka-Zhang Shaohe no-Hu Yule

Isikhathi sokuthumela: Aug-04-2023